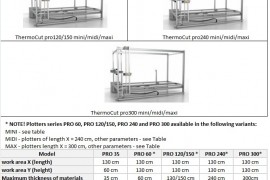

Thermal plotter is a computer numerically controlled lather (cnc) used to cut foams with the hot resistance wire. The effect of cutting is obtained by material evaporation in a hot environment of the wire (about 800 degrees). Cutting trajectory designed on a computer is done via stepper motor drives (6 pieces for the movement of X-Y axes + 1 for the rotary table).

Most models we offer can operate in the following modes.

“2.5D mode” In the simplest variant, cutting three-dimensional, third dimension of the object is obtained by the thickness of the harvested material – user designs two-dimensional object (text, logo, bar architectural strip, etc.) and third dimension arises according to dimensions of the used foam block (Styrofoam ). In this case Thermal Plotter movement is executed by cutting arms in X and Y axes.

“3D rotary mode” Thanks to using rotary table along with the lathe (available as standard equipment for all one wire plotters) thermal plotter based on the profile shaping of a solids of revolution drawn by the user executes movement in the X, Y axes, with axis of rotation positioned horizontally. Rotating 3D elements as columns, bullets and balusters are cut in this way. Additionally using shaped wire we can cut “threads”, internal column grooves or worm columns.

“3D full mode” Combining movement of X, Y axes along with vertically arranged rotary table allows to cut three-dimensional irregular shapes. Object is cut out from many two-dimensional profiles assigned to the appropriate angle of the material. Our software will automatically prepare a three-dimensional cutting project from three-dimensional imported models in RAW format. This way car model, human figure or virtually any other shape can be cut out.

“3D perspective mode” Using the independent movement of both cutting arms in the XY planes we can cut out regular cones or spatial elements with different bases on both sides on thermal plotter.

In all of modes our thermal plotters are controlled by an independent electronic controller supervising the work of all drives along with digital control of wire’s temperature.

Funcionality:

|

Construction:

|

anodized aluminium profiles with increased stiffness and mechanical strength. |

|

Continuing cutting after breaking resistance wire:

|

very practical function that saves users’ time and money. When cutting large and complex projects resistance wire might wear out and its rupture might occur. Thanks to continued cutting function there is no need to start from the beginning of the project and to dispose of the damaged material. After replacing the resistance wire Coner ThermoCut plotter resumes cutting from exactly where it finished. |

|

Rotary Cutting:

|

Rotary table, the standard equipment of thermal plotters ThermoCUT enables cutting out solids of revolution. Workpiece can be mounted vertically or horizontally. This allows to cut even three meters high spatial objects. Thanks to the combination of smooth rotation movement of material on the set path we obtain the functional equivalent of the lathe. |

|

Cut in two directions:

|

rotary cutting reduces the duration of the project execution twice by using the open shapes. |

|

3D Visualization:

|

Cutting irregular solids of revolution from many downloaded profiles can sometimes give unexpected results due to overlapping line cuts in three-dimensional space. To save time and material program allows you to view on the screen rendered spatial solid before cutting out. |

|

Independent cutting arms movement:

|

ThermoCut thermal plotter has a unique feature of cutting elements with perspective. Independent cutting arms movement under the control of advanced software allows to cut out solids with a different size and shape bases. Finally by one move we can cut out cones, pyramids, and letters with the effect of perspective. |

|

Remote control:

|

With the remote control, the need to control the plotter from the computer console can be avoided. Remote Control enables intuitive and convenient steering. Material tooling can take place directly under the control of the operator, who, thanks to the pilot can quickly control a plotter. The operator has an impact on the basic operating parameters such as speed and resistance wire’s temperature. Remote control also allows controlling the turntable. |

|

Titanium wire:

|

All of our machines are equipped with titanium cutting wire, which has greater strength and can work with higher speeds. |

|

Multiwires:

|

Solution that we offer allows to place on the shoulders of two to five cutting wires. Unique feature is the detection of each of the wires breaking separately and continuing exactly where the cut end. |

|

MultiWires machines:

|

Machines for heavier industrial applications for simultaneous cutting 15 full-wire machine workspace |

|

Equipment on request:

|

Coner also designs and manufactures thermal plotters of the specific, customer-defined sizes and with any number of cutting elements. Because of that Coner is able to create machines for even the most demanding customers |